Model preparation for 3D printing is a crucial step in the additive manufacturing process that involves converting a digital 3D model into a physical object layer by layer. The success of the 3D printing process largely depends on how well the digital model is prepared for printing.

Checking and Adjusting Scale

Checking and adjusting the scale of a 3D model is a crucial step in the preparation process for 3D printing. Ensuring that the dimensions of the digital model align with the intended physical size is essential for creating accurate and functional printed objects. Here’s a guide on how to check and adjust the scale of a 3D model:

1. Determine Desired Dimensions:

- Clearly define the intended size of the printed object. Consider the physical constraints of your 3D printer, the purpose of the object, and any specific requirements.

2. Open the 3D Model in CAD Software:

- Use computer-aided design (CAD) software to open the 3D model. Popular CAD programs include Autodesk Fusion 360, SolidWorks, Blender, and TinkerCAD.

3. Check Units and Scale:

- Verify that the model is set to the correct units (e.g., millimeters, centimeters, or inches). In many cases, 3D printing is done using millimeters. Check and adjust the scale if necessary.

4. Reference Dimensions:

- If the 3D model is based on real-world objects or has specific reference dimensions, use these to confirm the accuracy of the scale. Compare the dimensions of key features with the intended sizes.

5. Measure and Scale Verification:

- Use the measuring tools within the CAD software to measure critical dimensions of the model. Cross-check these measurements against the intended dimensions to ensure they match.

6. Adjust Scale:

- If the measurements don’t match the desired dimensions, scale the entire model uniformly. Most CAD software allows you to scale along specific axes or uniformly. Ensure that the proportions of the model are maintained.

7. Check Internal Structures:

- Some 3D models may have internal structures or components that also need to be scaled appropriately. Check for nested or grouped elements and ensure they are scaled consistently with the overall model.

8. Recheck and Iterate:

- After adjusting the scale, recheck the dimensions and iterate if necessary. It may take a few attempts to achieve the correct scale, especially if the model is complex or has intricate details.

9. Save and Export:

- Save the modified 3D model in the desired file format (e.g., STL) once the correct scale is achieved. This scaled model will be used for the subsequent steps in the 3D printing process.

Ensuring the accurate scale of a 3D model is fundamental to achieving the desired physical dimensions of the printed object. Taking the time to check and adjust the scale properly contributes to the overall success and precision of the 3D printing process.

Creating a Stable Base or Raft

Creating a stable base or raft is an important aspect of 3D printing, especially when dealing with models that have overhangs, small contact points, or require additional adhesion to the print bed. A stable base ensures proper adhesion during the printing process and minimizes the risk of warping or detachment. Here’s a guide on creating a stable base or raft for 3D printing:

1. Understand the Need:

- Determine whether your 3D model requires a stable base or raft. Models with small footprints, significant overhangs, or those prone to warping benefit from additional support.

2. Use Support Structures Wisely:

- Consider using support structures in conjunction with a stable base or raft. Support structures provide temporary scaffolding for overhanging parts, while the base ensures overall stability.

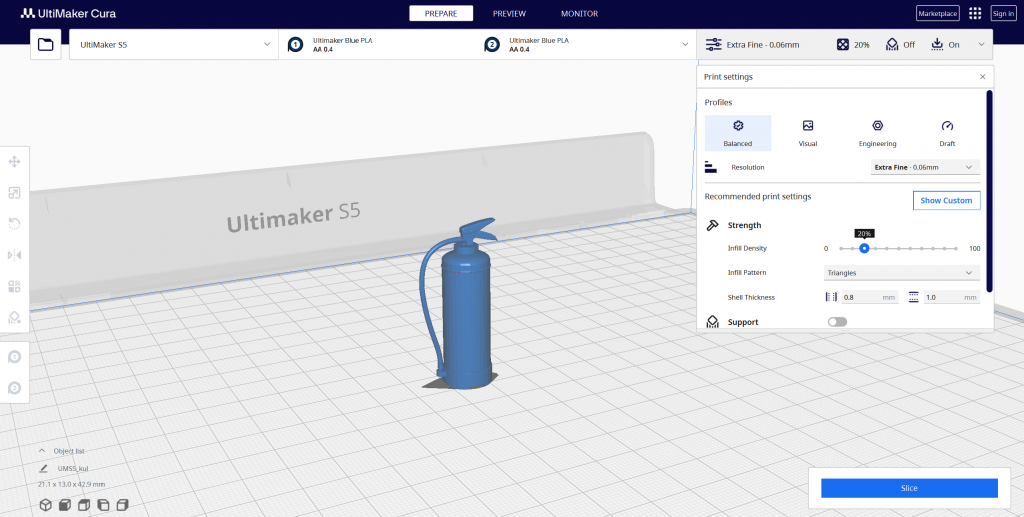

3. Enable Raft or Brim in Slicing Software:

- Most 3D printing slicer software allows you to enable features like raft or brim. Raft is a thicker layer beneath the print, while brim is a single-layer perimeter around the base. Enable the raft feature for models that require extra stability.

4. Adjust Raft Settings:

- Fine-tune raft settings in the slicing software. This includes adjusting the raft thickness, air gap between the raft and the model, and the number of raft layers. These settings depend on the specific requirements of your print and the characteristics of your 3D printer.

5. Consider Material Properties:

- Different 3D printing materials may require varying raft configurations. For example, materials like ABS tend to benefit from a raft due to their tendency to warp, while PLA may not always require one.

6. Set Raft Layer Height:

- Determine the appropriate layer height for the raft. This is usually thicker than the standard layer height and provides a solid foundation for the rest of the print.

7. Evaluate Raft Adhesion:

- Ensure that the raft adheres well to the print bed. Proper adhesion prevents the model from shifting during the printing process. Adjust the initial layer settings to enhance bed adhesion.

8. Check Model Placement:

- Confirm that the 3D model is appropriately placed on the print bed. Ensure that it doesn’t extend beyond the edges of the raft, as this can affect stability.

9. Raft Removal Considerations:

- Plan for the removal of the raft after printing. Some slicer software includes settings for making the raft easier to remove, such as adding perforations or reducing the number of layers.

Setting Print Tolerances and Clearances

Setting print tolerances and clearances is a crucial step in 3D printing, ensuring that the designed parts fit together accurately and function as intended. Tolerances refer to the acceptable deviation from the specified dimensions, while clearances are the intentional gaps between mating parts. Here’s a guide on how to set print tolerances and clearances for optimal 3D printing results:

1. Understand Material Properties:

- Different 3D printing materials have varying thermal and physical properties. Consider the material’s shrinkage and expansion characteristics when setting tolerances and clearances.

2. Design with Tolerances in Mind:

- During the initial design phase using CAD software, incorporate appropriate tolerances for parts that need to fit together. Consult material specifications and standards for guidance.

3. Test and Iterate:

- Conduct test prints to assess how well parts with specified tolerances fit together. If necessary, iterate on the design and tolerance settings to achieve the desired fit.

4. Consider Printing Orientation:

- The orientation in which a part is printed can affect tolerances. Layers have different adhesion strengths based on their orientation, and this can impact the overall size and fit of the printed part.

5. Account for Printer Precision:

- Be mindful of the precision capabilities of your 3D printer. The accuracy of the final printed part depends on the printer’s resolution, nozzle size, and other factors.

6. Adjust Tolerance Settings in Slicing Software:

- In the slicing software, adjust tolerance settings to compensate for any discrepancies in the printer’s accuracy. Some slicers allow you to customize tolerances for different parts of the model.

7. Clearance Considerations:

- Intentionally add clearances between mating parts to facilitate assembly. Clearances account for the imperfections in the printing process, making it easier to join components without the need for excessive post-processing.

8. Check for Interference:

- Ensure that the designed tolerances and clearances prevent interference between parts. Overly tight fits can lead to binding or jamming, while excessive clearances may result in loose connections.

9. Account for Temperature Variations:

- Consider the potential impact of temperature variations on part dimensions. Some materials may expand or contract with temperature changes, affecting the final fit.

10. Use Standard Tolerance Guidelines:

- Refer to industry standards and guidelines for general tolerances. Standards such as ISO 2768 define acceptable ranges for linear and angular dimensions, providing a baseline for tolerance considerations.

Setting precise tolerances and clearances is essential for achieving accurate and functional 3D prints. By understanding the properties of the printing material, iterating on designs, and adjusting settings in the slicing software, you can optimize the fit and performance of printed parts.

Conclusion

Preparing the model for 3D printing is a pivotal phase that significantly influences the success and quality of the final printed object. From the initial design phase to the actual printing process, careful attention to detail is essential. Proper model preparation involves considerations such as scaling, orientation, resolution, support structures, and material selection.

Addressing issues like non-manifold geometry, setting the correct file format, and optimizing the model for the chosen 3D printing technology are crucial steps that contribute to a seamless printing experience. The meticulous adjustment of parameters, including support structures and layer settings, ensures that the 3D printer can accurately translate the digital design into a physical object.

Furthermore, the incorporation of adequate tolerances, clearances, and stable bases or rafts adds a layer of precision to the printing process, enabling the creation of functional and accurately fitting parts. Regularly checking for printing artifacts and addressing issues such as layer adhesion problems, overhangs, or misalignments enhances the overall print quality.

In essence, successful 3D printing is a harmonious interplay between the digital design realm and the physical manufacturing process. As technology advances and user expertise grows, the art of preparing models for 3D printing continues to evolve. By staying informed about best practices, leveraging advanced software tools, and sharing knowledge within the 3D printing community, enthusiasts and professionals alike can unlock the full potential of additive manufacturing and bring their imaginative designs to life with precision and accuracy.